Special Reports

The Energy-saving Program of Shini

After the first photovoltaic program has been successfully put into operation in Dongguan plant in 2018, the second photovoltaic program on the rooftop of Automation Dept. building has also been completed in early October in 2018 to generate the power. The second photovoltaic program contains 2,346 photovoltaic modules of 275W that cover 9,550 sqm., with the capacity of 645kW and annual power output of 729,800 kWh. That means it saves 262 tons of coal and reduces carbon dioxide emissions of 645 tons every year, which not only makes the contribution in the energy saving for the society but also brings enormous economic benefits for its development!

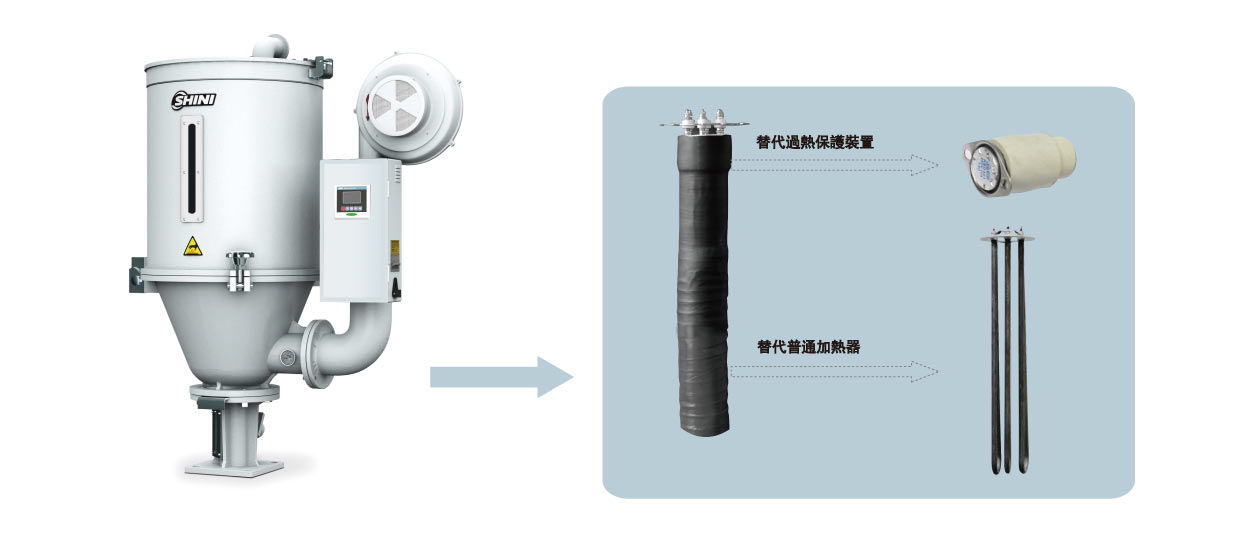

In addition to the energy saving purpose, Shini also aims to meet the customer’s demands for the power consumption and develops the energy-saving Hopper Dryer. It mainly uses the double- effect energy-saving heating rod made by the resistance with unique heating components to ensure the long service life. When the heating temperature reaches the critical value, its resistance will increase rapidly, some of the resistance parameters will climb several magnitudes, and the current through the heating rod will decrease sharply, which reduces the power, so that the temperature will not rise anymore, and it always maintains a certain degree.

The advantages of energy-saving Hopper Dryer:

1.Equipped with the microcomputer control and RS485 communication interface to achieve central system control;

2.The heater adopts double-effect energy-saving heating rod that saves 15-30% power consumption, and the heating rod has self-protection function that won’t damage the machine due to the blower and contactor failure.

3.Adopt a high-performance hot air diffusion device, excitation release overheat protector, and heat-insulation blower, with overheat release function.

Energy-saving data tested on the site of customer’s plant

The annual power consumption is calculated based on 24 hrs/day, 28 days/month and 12 months/year.

(The cost-saving calculated on the industry standard of 0.6 RMB/kWh.)

Special Reports

- Central Material Distribution Station

- Detachable Silo

- The Application of Hot-runner Valve Multi-cavity System

If you want to read other articles, back to2019 Quarter 1 Issue 38.