Special Reports

The Usage of Heatless Air Dryer

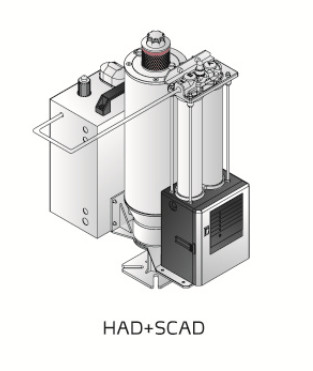

HAD is an equipment mainly used to dehumidify plastic materials, especially the engineering materials that demand certain moisture content of dry air. It can work with SDL-U, SCAD and SHD-U.

Compared with conventional honeycomb dehumidifier, HAD enjoys several advantages, including high efficiency of energy conservation, compact structure, easy installation, convenient maintenance, etc. It is particularly suitable for conditions in which materials are seldom used but their dryness is strictly stipulated, such as 3D printing. When working with SDL-U, HAD can be installed at the back of it. Therefore, the dew point of drying wind can be lowered and the stability and quality of products can be ensured.

When working with SCAD, HAD can be installed in many ways. For example, it can be fixed on the rack or be connected with SCAD by connection plate.

HAD is optional for SHD-U to speed up dehumidifying raw materials.

HAD can be used alone, and it can also work with other machines in accordance with customers’ need, providing drying wind with low dew point to customers.

Special Reports

- The Significance of COP to Cooling System

- Central Material Conveying System

- Vertical Rotary Discharge Valve LRV40

If you want to read other articles, back to2017 Quarter 4 Issue 33.