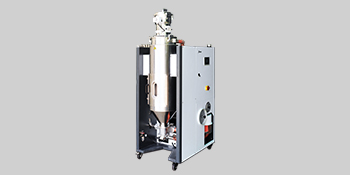

Drying and Dehumidifying

The dehumidifying series has been developed for drying plastic materials with a steady dew-point air as low as -40℃ with a maximum drying capacity of up to 1,150kg per hour (in the case of PET).

Feeding and Conveying

Dosing and Mixing

Heating and Cooling

Granulating and Recycling

Shini Sound-proof Central Granulators are suitable for centralized recycling of wastes or rejects from injection moulding and blow moulding, featuring robust structure, simple operation, and quick blade replacement. These series have various models with broad applications to cater to your needs.

Automation System

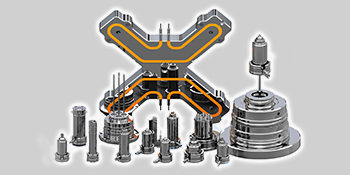

Hot Runner System

To ensure the strength and the special requirements of products, the nozzle length can be from 40mm to 500mm. Each set of hot runners is professionally analyzed with mould flow software and mature composite technology.

Systematic Solution

-

Drying and Dehumidifying

The series is split into a hot air dyer and dehumidifying dryer.More

The dehumidifying series has been developed for drying plastic materials with a steady dew-point air as low as -40℃ with a maximum drying capacity of up to 1,150kg per hour (in the case of PET).

-

Feeding and Conveying

Feeding and conveying series are capable of auto dedusting and alarms of material shortage via digital microcomputer controller. The conveying of material is done in a control loop cycle, designed to reduce material loss and control the material from regaining moisture during the conveying process.More -

Dosing and Mixing

Mixing and Dosing series offers various solutions for the dosing, metering, and mixings of material, such as plastic virgin material, regrind pellet, masterbatch, additive, and free flow power. With the throughput ranging from 0.1 kg/hr to 3,000kg/hr, up to 8 groups of components can be simultaneously handled, and the precision from ±0.1% to ±0.3%.More -

Heating and Cooling

The series is split into a heating or chilling unit. Mould Temperature Controllers are designed for heating moulds and maintaining temperature. In contrast, a Water Chiller unit is intended for cooling moulds rapidly and reducing the unit's cycle time. The heating units have the option of water or oil medium and have a maximum temperature of up to 350℃, and the water chiller has a cooling temperature of 7℃.More -

Granulating and Recycling

Shini Low-speed Granulators are designed for instant granulating and recycling sprues and a small number of rejects next to the injection machine. It is equipped with dual-safety devices and conforms to European Safety Standards.More

Shini Sound-proof Central Granulators are suitable for centralized recycling of wastes or rejects from injection moulding and blow moulding, featuring robust structure, simple operation, and quick blade replacement. These series have various models with broad applications to cater to your needs. -

Automation System

Shini Automation is designed for removing sprues and taking out finished products from injection moulding machines. It is available for the application of IML, mould insertion, top entry or side entry 2-plate, 3-plate mould, and hot runner mould.More -

Hot Runner System

It's suitable for materials whose flow gates are in the range of Ø0.6-Ø0.8. The frame can be opened to Ø12 at the hot nozzle of the mould.More

To ensure the strength and the special requirements of products, the nozzle length can be from 40mm to 500mm. Each set of hot runners is professionally analyzed with mould flow software and mature composite technology. -

Systematic Solution

Shini is always there to help you enhance marketing effectiveness, quality, and competitiveness. Shini can cater to different needs by providing customized plant planning in plastic material handling solutions, such as in conveying, drying, dosing, temperature control and system cooling, automation, and recycling for injection or extrusion applications.More

Years of Experience

Years of Experience Collaborators

Collaborators Offices in the world

Offices in the world Service and Sales

Service and Sales

Company

User-oriented:

On customer searvice, Shini adopts considerable and flexible ways to meet all kinds of requirements.

Humanization:

On product design, Shini adheres to user-friendly principle; by improving new technologies to realize design humanization to the maximum.

One-stop:

On business cooperation, Shini provides one-stop experience, and creates trustful and friendly long-term cooperation.

News & Events, Notifications

We continue to provide you with the latest information and news of the business department. The general communication and current affairs of Shini are here at a glance!

More News & Events, Notifications →

-

2024-06-24

As a leader in plastic material handling equipment, Shini Group has always maintained a steadfast commitment to a professional attitude, innovative spirit, and customer-oriented service concept since its establishment, earning the title of champion in this industry. Over the past 55 years, we've toiled tirelessly, often burning the midnight oil, overcoming numerous challenges with unwavering belief, and embarking on a remarkable journey. Time may pass, but like a spark that never fades, Shini continues its relentless pursuit of development, always striving for the next milestone.

MoreA New Era in the Future, 55 Years of Remarkable Innovation

-

2024-05-08

On April 23rd 2024, the international rubber and plastics exhibition Chinaplas 2024 was held in Shanghai National Convention and Exhibition Center, marking a significant milestone after six years from its last show. The event, which successfully concluded on April 26th , spanned an impressive total area of about 380,000 square meters. It drew over 4,400 exhibitors and a staggering total of 321,879 visitors , making it a truly remarkable technological feast in the industry.

More【Shini Group】Chinaplas2024 rounded off successfully

-

2022-10-13

On October 4th, 2022, Shini held the groundbreaking ceremony for a new facility in Hanoi. All were dipped in a cheerful atmosphere on that day.

MoreWe are expanding, Shini new facility at Hanoi Vietnam

-

2022-10-13

Guten Tag, K is back. K show is one of the most influential international trade fairs for the plastics and rubber industry, held every three years. The K welcomes every plastic people to the beautiful city of Dusseldorf, Germany, from October 19th to 26th. Including over 3000 exhibitors, K will be the most important trade show for the industry after the Covid-19 pandemic.

MoreAt last, K 2022, we are coming!

Worldwide

Find your local contact

The Shini global market presence extends throughout the world, where our customers are going and where they're growing.

Shini newsletter

Get a regular update on the latest developments in our products, with current news, information about the Shini, and the newest content.