Special Reports

The Application of Shinzo Hot Runner Nozzle

The nozzle is the terminal of the hot runner system and also the end part of the heating and gate, which is used for conveying the melt to the mold cavity or additional cold runner. It is a complex component that has many unique demands of high technologies in addition to general manufacturing requirements of the hot runner system. To prevent changes in flow properties, the melt temperature in the runner is constant, and the temperature distribution characteristic needs to approach a straight line.

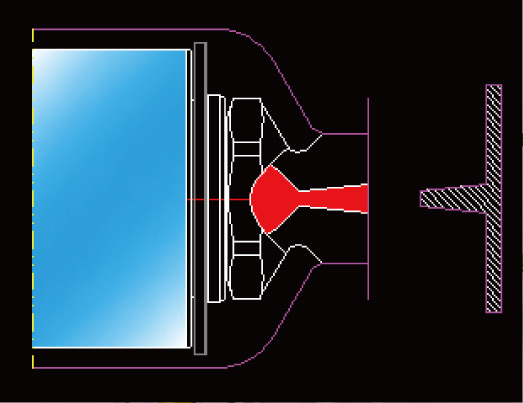

Large open sprue nozzle

Large open sprue nozzle

This kind of nozzle has no requirement of gate size in the application that usually has a relatively large gate in diameter of 1-4mm. The open nozzle will leave the sprue melt on the plastics surface or cold runner, but it can keep good packing pressure and reduce the stress in the injection, which is mainly used for engineering parts injection, and the trace left on the parts is not important. Also, this nozzle is often applied in main short runner and cold runner injection but not suitable for plastics that are easy to generate wire drawing.

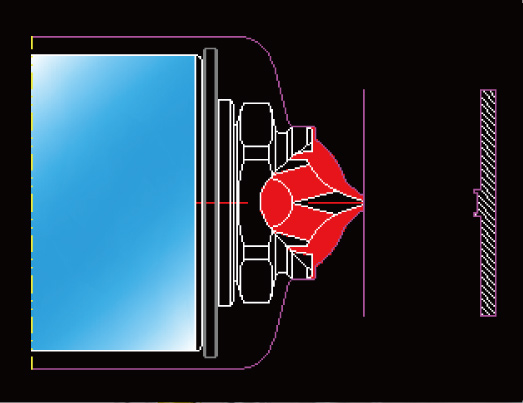

Open sharp nozzle

Open sharp nozzle

This kind of open sharp nozzle allows direct injection on the product surface, which features a small gate trace, good appearance, and less waste remains in products. Both amorphous and crystalline plastics require this kind of nozzle that makes it easy to inject the temperature-sensitive plastics and control the temperature from the nozzle core to the gate. Its gate diameter of 0.6-2.5mm is relatively small that leaves very low round wastes it formed with the thimble on the surface of the parts. The sprue size depends on the gate structure and size, plastic property, and gate cooling state, and the smaller the gate diameter, the less the waste material. The nozzle sharp is in the center of the gate, which helps to prevent wire drawing.

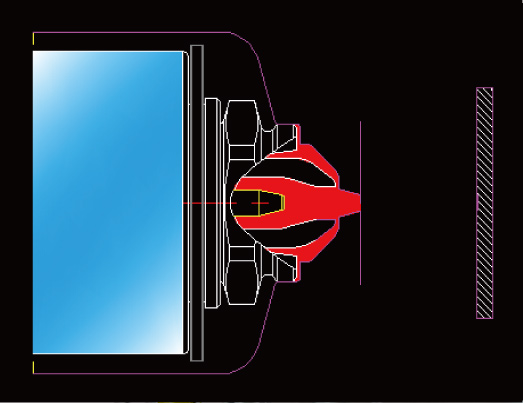

Valve nozzle

Valve nozzle

The movable valve pin is threaded into the gate hole that drives the gate to close mechanically. This design allows a large diameter gate to fill the cavity easily, which is especially suitable for high-viscosity or shear-sensitive plastics and can maintain relative long holding time so that the hot runner system can be used for thick wall plastic parts. Gate closing eliminates the influence of heat balance in the gate area, accurately controls the pressure maintaining state, and improves the plastic parameter's accuracy. It has an instantaneous gate closing function to prevent flashes on the structure due to high-pressure melts overflowing after the cavity is filled, restricting the gate to flow and draw wires, which only leaves traces around the valve pin on the molded parts. This kind of nozzle is suitable for products with high cosmetic requirements.

Special Reports

If you want to read other articles, back to2020 Quarter 1 Issue 39.