Special Reports

Intelligent Flow Regulator —— Your Flow Controller!

How to control the mold temperature? Generally speaking, the constant-temperature medium is conveyed into the runner of the mold so that it can control the temperature in each mold area. If the demands for temperature are different, several sets of temperature control equipments can be used to control the mold temperature by area. Therefore, essentially, the mold constant temperature is indirectly maintained by external thermostat equipment through medium circulation. As the medium circulates in the mold runner, the pressure and flow of the medium are very important for maintaining constant mold temperature. Especially for precise or large injection-molded products, temperature homogeneity and distribution consistency can fundamentally determine the quality of the products.

Then, how to monitor the medium flow of each mold runner effectively? When the mold pipeline is blocked, what we should do if the mold temperature can’t be controlled within the set temperature that resulting in defective products? How to check the actual runner and temperature of each runner more effectively and conveniently? Shini latest product of Intelligence Flow Regulator SIFR can help you to find out the reason.

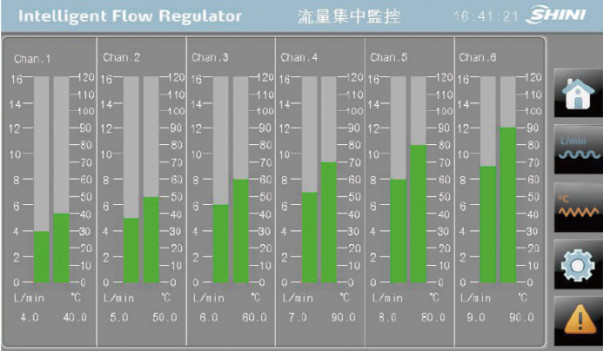

SHINI Intelligence Flow Regulator SIFR is the equipment used for monitoring the water flow and temperature, which can work with the water heater, water chiller or cooling tower to monitor the mold water loop and obtain data. It is available to collect the temperature and flow data in production, providing strong support to achieve and improve the technology. When the product has defects, the problem can be eliminated by rapid positioning, thus fulfilling precision manufacturing with improved efficiency.

This product equips with the 7'' touch screen, and its simple operation in the direct display is easy to operate. Each group of loop corresponds with a group of data to achieve synchronous temperature and flow measurement. Meanwhile, it also has the flow trend, temperature trend and flows abnormal alarm function. Once the flow or temperature is abnormal, the alarm signal will send out. Besides, the pipeline state can be prejudged by the flow curve, and the problem will be controlled at the preliminary stage.

The use of Intelligent Flow Regulator is very convenient that it only need connecting the pipeline correctly through the power before use without lots of settings. Available to be used with the optional mounting frame, it also can be installed on the injection molding machine. The compact structure design makes for good space utilization, and reasonable pipeline design ensures stable flow and accurate data. Besides, Shini also provides the hose connector and air pipe connector for the customer to choose.

As a smart product, it cannot miss the data communication function. This product has the standard RS485 communication interface to support Modbus-RTU protocols, making interconnection and intercommunication between devices, while realizing centralized monitoring, data acquisition analysis, and production process parameter tracing functions.

Special Reports

If you want to read other articles, back to2018 Quarter 4 Issue 37.