Special Reports

What Does SSW Bring to the Customer?

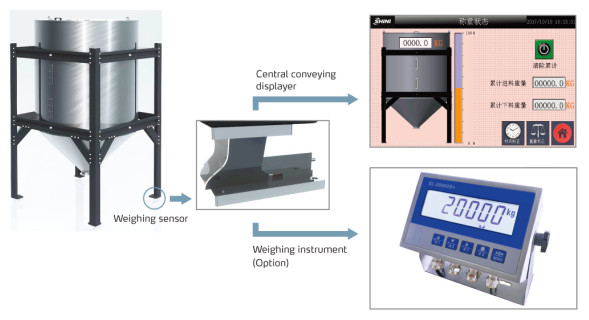

The load cell technology is a kind of sensor based on analog control that can transfer some energy to another form, which causes the change of strain gauge resistance through external pressure variation to output the current or voltage, and pass the weight signal to the junction box. The paralleling signals of weighing module in the junction box that can adjust the angular difference in accordance with the load condition of each weighing module. After collection, the signals are sent to the weighing end or weight transmitter, which process the weight signal to corresponding weight data.

With development of times and progress in science and technology, the scale of plastics injection industry is growing, and the demand for material controlling is increasing, which not only focuses on the quality, but also has high demand on the cost. How to control the consumption of the material effectively requires the control from the source. However, according to our practices, the application of weighing sensing technology in central conveying system can properly solve this problem.

The SSW is the real-time weigher based on PLC control and advanced load cell module, which has weight correction function to display real-time accumulative input and output weight for convenient control of material throughput. According to actually measured results, the error of output weight and accumulative output weight is 0.5%, and the error of input weight and accumulative input weight also is 0.5%.

When the material is used in the central feeding system, the dosage will be automatically recorded: the amount of materials left in the storage hopper before feeding will be indicated in the displayer and also be cleared. It’s unnecessary to remove the residual in the hopper, which omits a part of operations, and also can real-time display material weight and each accumulative weight in the storage hopper during the feeding. Moreover, it can give customers better understanding of the material throughput in the processed product, and the lost amount also can be real-time monitored in a glance. The record is free of manual that saves time and improves the working efficiency greatly, and it’s convenient for the customer to make report of cost analysis.

SSW has high precision that can meet actual requirement of the customers so that they can choose different weighing modules in accordance with different accuracy requirements. The module mainly has domestic module and import module, and the latter accuracy is higher than the former; the load cell modules of different rated capacities can be chosen based on different hopper capacities. In application, the standard SSW is integrated in the central conveying system that processes data acquisition and displays complete contents via central control station in the system. When it is needed to be used alone, the display instrument can be optional, but display contents are relatively simple.

In addition to above features, SSW also has the convenience that free from the site limit, flexible assembly, convenient maintenance and long service life, which ultimately helps users to improve material metering and material throughout control in the production.

Special Reports

If you want to read other articles, back to2018 Quarter 2 Issue 35.