Experience Sharing

Case of Shini Mold Temperature Controller and Data Acquisition System

Overall Design of System

Shini opened the communication interface of the mold temperature controller and data acquisition system provided to one factory of Foxconn and connected it to ERP system of the client as requirement, achieving monitoring and linkage control of all production equipments in the workshop.

System Function

Achieve real-time state remote control of the mold temperature controller

Achieve remote control of the mold temperature controller

Generate data report for customer to check and analyze

Soft open data interface and data integration of IMM and ERP

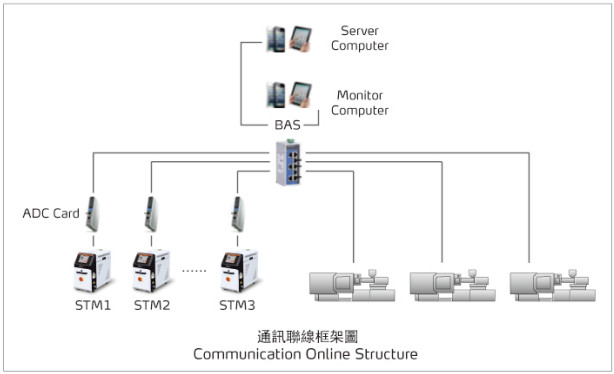

System Overall Structure and Description

The system adopts the standard RS485 communication interface equipped by Shini mold temperature controller to transform RS485 communication to Ethernet communication interface through the gateway (ADC card), and multiple mold temperature controllers are connected to the gateway (BAS) after transformation. Via the monitoring computer of workshop, it monitors and collects all the data of the mold temperature controller, and creates the database. Customer’s server computer server reads the data in database of the monitor computer, and integrates related data of the mold temperature controller, injection molding machine and ERP at the computer server end.

Experience Sharing

- Case of Plant Solution for Doors and Windows Motor Products

- Case of Central Conveying System in Package Industry

- Case Studies - Automation Application in Electrical Appliances Industry

If you want to read other articles, back to2018 Quarter 1 Issue 34.