Overview

Date: September 18th- 21th , 2014

Venue: Chongqing International Expo Centre, Chongqin

Exhibition Contents: full coverage of all plastics & rubber industry. The five categories include production equipment, auxiliary equipment & accessory, material and plastics, mould as well as the parts.

Events Introduction: 2014 China Midwest (International) Plastics & Rubber Exhibition (“CMI-PLAS2014”) was opening in Chongqing International Expo Centre. This exhibition held corporately by China Plastics Machinery Industry Association and Chongqing International Expo Centre, received supports from Chongqing and domestic organizations. Exhibition area covered 23,000 square meters.

The exhibition gathered outstanding enterprises of HAITAIN, YIZUMI, BORCH and SHINI in plastics auxiliary industry, received active supports and anticipation from American, Italian, Russian, England, Turkish, Spanish, Canadian, Malaysian, Thai, Brazilian plastics industry association and relevant international plastics industry association & organization.

Sharing

the sponsor introduced that Chongqing plastics industry develops and follows the domestic and entire plastics industry tendency. It exceeds domestic average developing scale with fast speed. Automobile and motorcycle is the key industry of Chongqing which reached total amount of 3,330 hundred million RMB in 2012. The total automobile sales reached 2.5 million and ranked No.3 in the nation. In 2020, it is estimated that the automobile industry may reach total value of 600 billion.

Chongqing plastics possess wide application and enable to obtain strong supports from multiple suppliers in the development, include plastic film, plate, pipe and the accessory, plastic foam, packing case and container as well as daily use products above ten fields.

Spotlight

Based on refrigeration technology of industry standard

For in the long terms, water chiller applied in industry without any relevant industry standard for confirmation, the majority of manufacturers designed the water chiller as refrigerant standard in air-conditioner industry. But the working condition of water chiller used in industry has large difference with the air conditioners. For example, the ordinary environmental temperature of air conditioner is 26~35℃, but the stable operation of water chiller requires wider range of environmental temperature, such as 10~30℃. For above reasons, water chiller used in industry which manufactured as the air-conditioner standard is relatively has lower reliability.

As to improve the reliability of water chiller and lower failure rate of water chiller used in industry, we revised its operation standard, adopted grand new of its inner structure and production process to make it reach the maximum working requirement in the industry. In addition, we are going to equip the water chiller in new model with a specialized controller. The new kind of controller can read operation datum directly and display them in letters which helps the user to obtain the information when machine is in operation.

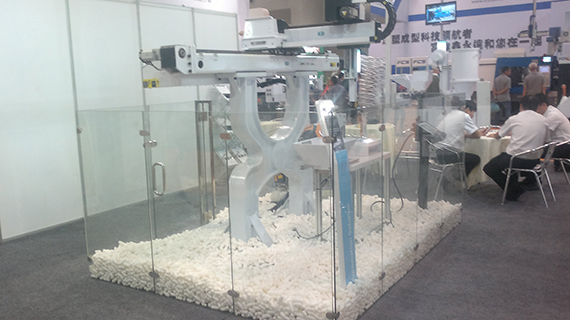

High-speed pick up the plastics

This exhibition displayed a High-speed Three Axes Servo Driven Robot ST3-700-1400HT. Its free circulation cycle within maximum speed of 5 seconds is applicable to 2-plate mold or hot-runner mold. It is capable of arranging stacking, quality checking and in mold placement with prompt pick-up speed which can largely improve production efficiency.

Energy-saving Hopper Dryer SHD-EH

Shini energy-saving hopper dryer SHD-EH adopts energy-saving heater to efficiently make use of heat to dry material, which saves13~30% energy more than the traditional heater. In addition, the machine is of safe operation, since it won’t be damaged by the high temperature which is caused by the machine failure.

Having over temperature tripping function, it will automatically cut off the power supply to protect the material against blocking when the drying temperature exceeds the set deviation value. The energy-saving heater uses a special made resistance to heat up. When the heating temperature reaches to a critical value, the resistance value will go up rapidly, sometimes even increase by several orders of magnitude. Consequently, the current going through the heater will rapidly decrease, which actually makes the power reduce to make its temperature not go up any more and keep it in a certain temperature to ensure safe operation.